The excavator is a large-scale mechanical equipment widely used in construction, mining, agriculture and other fields. In order to ensure the normal operation of the excavator and extend its service life, routine maintenance is very important. This article will introduce you to the daily maintenance tutorial of the excavator.

1. Daily inspection

1. Appearance inspection: Before use every day, the appearance of the excavator should be checked for damage, looseness, etc. If any abnormalities are found, they should be dealt with promptly.

2. Lubrication inspection: Check whether the lubricating oil and grease in various parts of the excavator are sufficient. If there is any shortage, add it in time. At the same time, lubricating oil and grease should be replaced regularly.

3. Hydraulic oil check: Check whether the hydraulic oil of the excavator is sufficient. If there is insufficient, add it in time. At the same time, the hydraulic oil should be replaced regularly.

4. Coolant check: Check whether the coolant of the excavator is sufficient. If there is insufficient, add it in time. At the same time, the coolant should be replaced regularly.

5. Fuel check: Check whether the excavator has sufficient fuel. If there is insufficient fuel, add it in time. At the same time, the fuel should be replaced regularly.

2. Daily maintenance

1. Cleaning: After daily use, the surface and interior of the excavator should be cleaned to prevent dust and debris from entering key parts. Can be cleaned with a soft cloth and detergent.

2. Lubrication: According to the usage of the excavator, lubricate the lubrication points of each part regularly. When lubricating, make sure the quality and quantity of lubricating oil and grease meet the requirements.

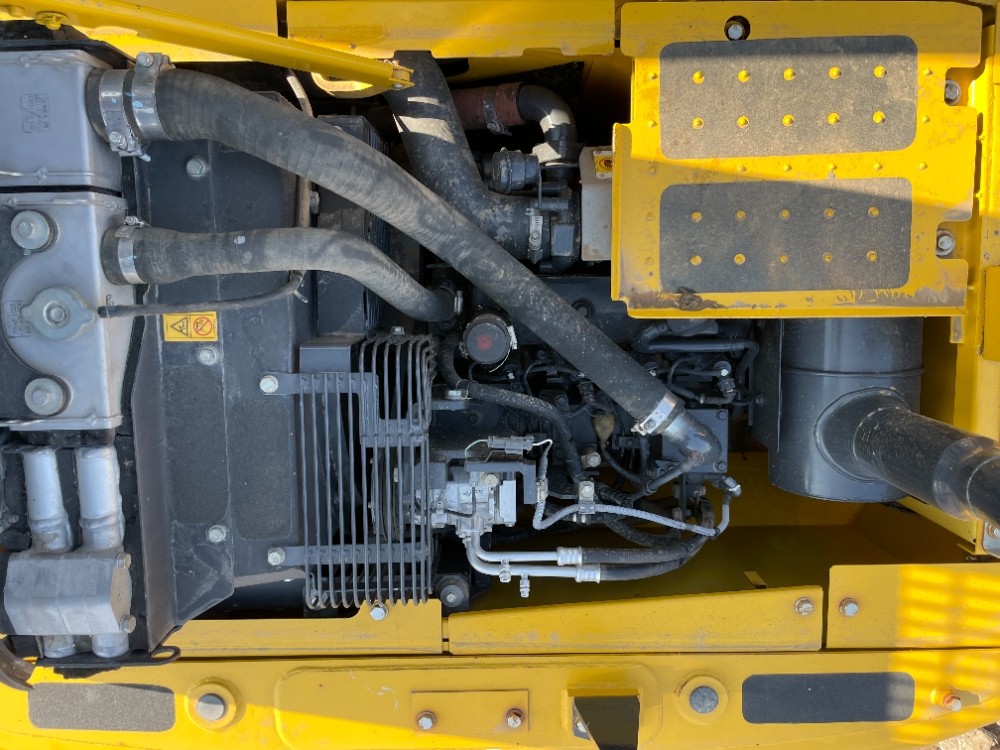

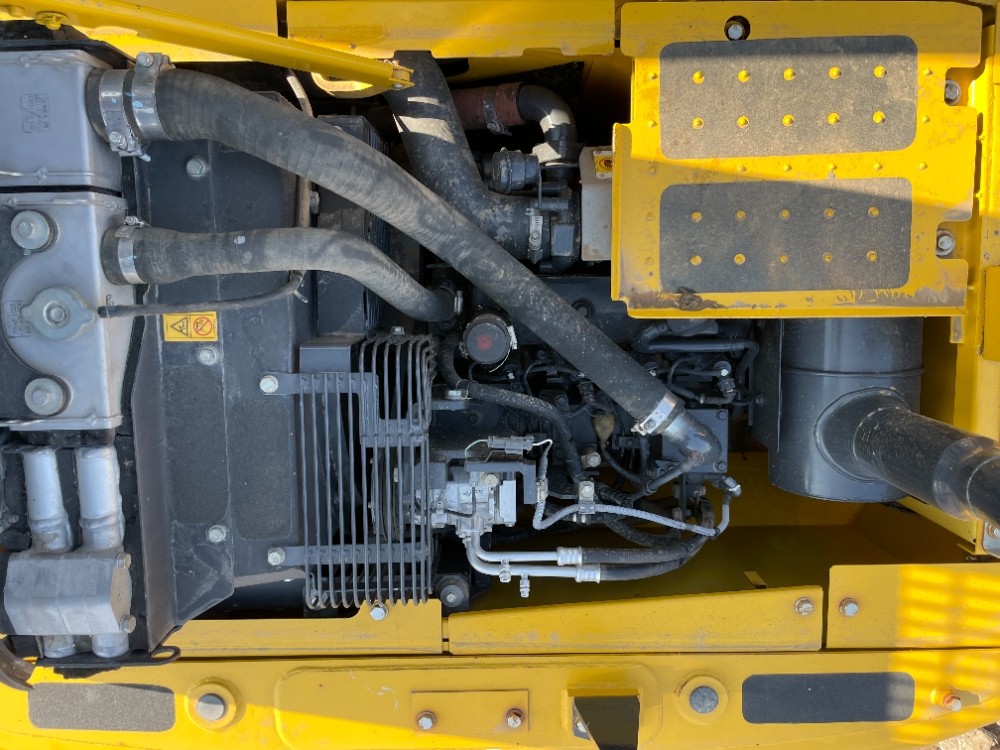

3. Filter element replacement: Regularly replace the air filter element, fuel filter element and hydraulic oil filter element of the excavator to ensure the normal operation of the engine and hydraulic system.

4. Belt adjustment: Regularly check the tightness of the excavator's belt. If it is inappropriate, adjust it in time. When the belt is severely worn, it should be replaced in time.

5. Tire inspection: Regularly check the tire pressure and wear of the excavator. If there is any deficiency, inflate or replace the tires in time.

3. Regular maintenance

1. Engine maintenance: Carry out engine maintenance regularly according to the usage of the excavator. Maintenance includes replacing engine oil, engine filter, air filter, fuel filter, cleaning throttle valve, cleaning fuel injectors, etc.

2. Hydraulic system maintenance: Carry out regular maintenance on the hydraulic system according to the usage of the excavator. Maintenance includes replacing hydraulic oil, oil return filter element, pilot filter element, cleaning hydraulic oil tank, etc.

3. Electrical system maintenance: Carry out regular maintenance on the electrical system according to the usage of the excavator. Maintenance includes checking whether line connections, fuses, relays, switches, etc. are normal, cleaning battery terminals, etc.

4. Braking system maintenance: Regularly check the excavator's braking system, including brake pads, brake drums, brake oil pipes, etc. If it is worn or damaged, it should be replaced in time.

5. Structural parts maintenance: Regularly check the structural parts of the excavator, such as booms, buckets, etc. If there are deformations, cracks, etc., they should be repaired or replaced in time.

4. Precautions

1. When performing daily maintenance on the excavator, be sure to follow safe operating procedures to prevent accidents.

2. When replacing lubricating oil, grease, hydraulic oil and other liquids, make sure they are drained cleanly to prevent environmental pollution.

3. When performing maintenance on the excavator, use qualified tools and accessories to ensure the quality of the repair.

4. Conduct comprehensive inspections of the excavator on a regular basis, and solve problems in a timely manner to prevent small problems from turning into major failures.