Recommend Products

-

$11,500$12,500

-

$9,000$10,500

-

$49,000$54,000

-

$58,000$60,000

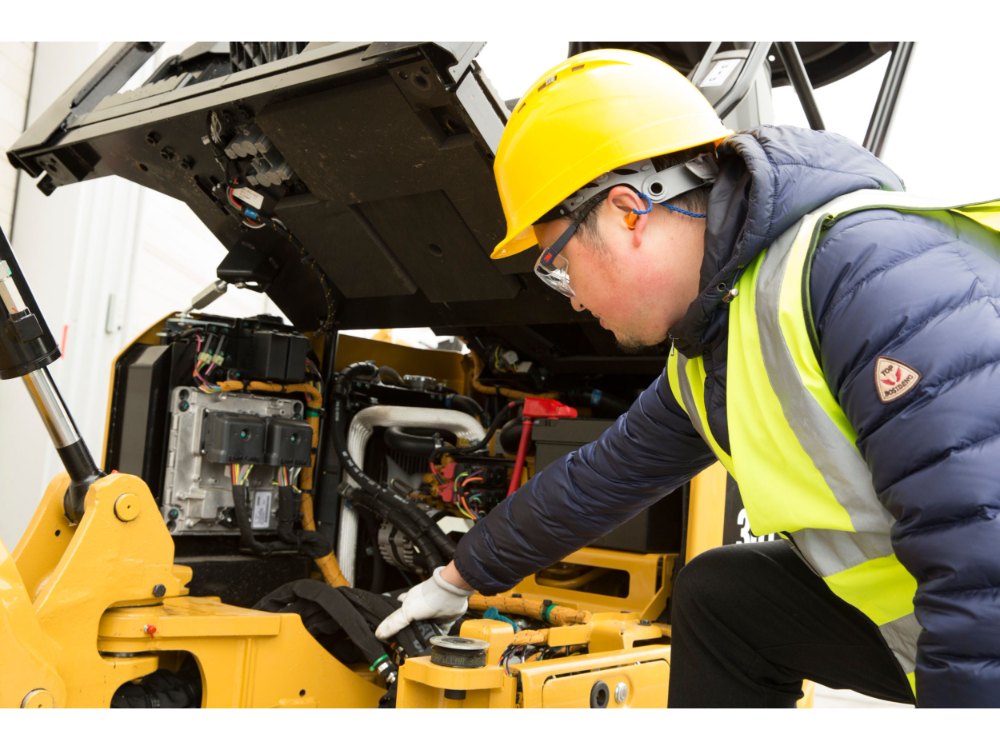

Excavator fault codes are feedback from users when using the equipment in the excavator to inform the user of possible or existing mechanical or electronic faults in the excavator, which can influence the equipment maintenance and repair of the excavator in advance. Here is a friendly reminder that the failure rate of excavators is very high. Each Brands have different fault codes. It is impossible for users to remember all the fault rates. However, the 30 common and more important fault codes introduced today should be remembered as much as possible to avoid fault codes found during use and failure to take timely measures. Excavator equipment damaged again

The failure rate of excavators excludes the defects that are likely to occur after the manufacturer leaves the factory. Most of the failures will be caused by equipment failure or false alarms caused by operation or working environment. As excavator sensors, there will also be fault reports. All users can understand by understanding Or to troubleshoot excavator problems. Once an important core fault code occurs unnecessarily, the user must shut down the machine for maintenance. Within the warranty scope, the manufacturer's model will receive free maintenance and repairs. If the warranty exceeds the warranty scope, the maintenance personnel must be contacted as soon as possible for maintenance measures.

1. E4039-92: High-pressure oil pump failure

- Treatment method: Check whether the oil supply of the high-pressure oil pump is normal, check whether the oil pressure is stable, and replace the high-pressure oil pump if necessary.

2. E4503-02: Engine temperature is too high

- Solution: Check whether the engine coolant is sufficient, check whether the cooling system is normal, clean the radiator, and check whether the water pump is operating normally.

3. E3018-16: Air filter clogged

- Treatment method: Clean or replace the air filter to ensure air circulation.

4. E3002-12: Fuel filter clogged

- Solution: Clean or replace the fuel filter, and check whether the fuel pipeline is smooth.

5. E3200-01: Low engine oil pressure

- Solution: Check whether the engine oil is sufficient, check whether the oil pump is operating normally, and check whether the oil line is blocked.

6. E3401-05: Low coolant pressure

- Treatment method: Check whether the coolant pump is running normally, check whether there is leakage in the coolant pipeline, and check whether the radiator is blocked.

7. E5119-11: Steering hydraulic pump pressure is low

- Treatment method: Check whether the steering fluid level is sufficient, check whether the steering fluid pump is normal, and check whether there is leakage in the steering system.

8. E5410-14: Braking system failure

- Treatment method: Check whether the brake fluid level is sufficient, check whether the brake is stuck, and check whether there is leakage in the brake system pipeline.

9. E5502-09: Hydraulic system pressure is too high

- Treatment method: Check whether the hydraulic oil filter is clogged, check whether the hydraulic oil pump is normal, and check whether the hydraulic cylinder is stuck.

10. E1003-04: Engine control module (ECM) failure

- Treatment method: Check whether the ECM power supply and ground wire are normal, check whether the connection between the sensor and the actuator is good, and replace the ECM if necessary.

11. E2201-07: Air pressure sensor failure

- Solution: Check whether the air pressure sensor connection is good, check whether the sensor is damaged, and replace the sensor if necessary.

12. E2502-03: Coolant temperature sensor failure

- Solution: Check whether the coolant temperature sensor is well connected, check whether the sensor is damaged, and replace the sensor if necessary.

13. E6001-12: Oil level sensor failure

- Solution: Check whether the oil level sensor is well connected, check whether the sensor is damaged, and replace the sensor if necessary.

14. E3503-08: Hydraulic oil temperature is too high

- Treatment method: Check whether the hydraulic oil cooler is normal, check whether the hydraulic oil filter is clogged, and check whether there is leakage in the hydraulic system.

15. E5205-15: Transmission system failure

- Treatment method: Check whether the fluid level in the transmission system is sufficient, check whether there is leakage in the transmission system pipeline, and check whether there is any abnormal noise in the transmission system.

16. E6111-05: Generator output voltage is low

- Solution: Check whether the generator drive belt is loose, check whether the generator connection is good, and check whether the battery is charging normally.

17. E7502-02: Frame sensor failure

- Solution: Check whether the frame sensor connection is good, check whether the sensor is damaged, and replace the sensor if necessary.

18. E8100-13: Hydraulic cylinder leakage

- Treatment method: Check whether the hydraulic cylinder seal is worn, check whether there is leakage in the hydraulic pipeline, and replace the hydraulic cylinder seal if necessary.

19. E9003-11: Brake valve failure

- Solution: Check whether the brake valve connection is good, check whether the brake valve is stuck, and replace the brake valve if necessary.

20. E9304-06: Oil pressure sensor failure

- Solution: Check whether the oil pressure sensor is well connected, check whether the sensor is damaged, and replace the sensor if necessary.

21. E2102-09: Water temperature sensor failure

- Solution: Check whether the water temperature sensor is well connected, check whether the sensor is damaged, and replace the sensor if necessary.

22. E3101-14: Fuel temperature sensor failure

- Solution: Check whether the fuel temperature sensor is well connected, check whether the sensor is damaged, and replace the sensor if necessary.

23. E4305-01: Oil temperature sensor failure

- Solution: Check whether the oil temperature sensor is well connected, check whether the sensor is damaged, and replace the sensor if necessary.

24. E7103-10: Oil leakage

- Treatment method: Check whether there is leakage in the hydraulic pipeline, check whether the seals are worn, and replace the seals if necessary.

25. E8201-03: Drive shaft failure

- Treatment method: Check whether the transmission shaft is well connected, check whether the transmission shaft is cracked or deformed, and replace the transmission shaft if necessary.

26. E9502-08: Hydraulic filter clogged

- Treatment method: Check whether the hydraulic filter is clogged. If necessary, clean or replace the hydraulic filter.

27. E3202-04: Cooling fan failure

- Solution: Check whether the cooling fan connection is good, check whether the fan drive system is normal, and replace the fan if necessary.

28. E3601-06: Coolant pump failure

- Treatment method: Check whether the coolant pump connection is good, check whether the pump blades are worn, and replace the coolant pump if necessary.

29. E5304-11: Transmission system filter clogged

- Treatment method: Check whether the transmission system filter is clogged. If necessary, clean or replace the transmission system filter.

30. E6502-07: Brake pad wear

- Treatment method: Check the brake pad wear and replace the brake pad if necessary.

The above TD introduces the analysis and solutions of 30 common failure rates of Caterpillar CAT. Of course, there are certain differences in the failure rates of some models. For details, you need to read the manual and consult the local seller. Excavator failure is a very common situation. , it is necessary to observe before daily use and maintenance work, which can greatly reduce excavator failures and increase the service life of the excavator. Users who need to replace or purchase new accessories can do retail or wholesale through TD.