Recommend Products

-

$37,000$39,000

-

$27,000$31,000

-

$17,000$20,000

-

$14,000$18,000

The use standards and replacement of hydraulic oil have very strict requirements for excavator operators and users. As an important part of excavator maintenance, the excavator hydraulic pump does not require replacement cycles depending on the use environment and work type, especially for excavator excavation. The "blood" of the machine has very strict quality requirements for hydraulic oil. Hydraulic pump replacement can be done at the manufacturer or dealer in the early stage, but in the later stage, most people will replace it personally to reduce usage costs. So how to choose hydraulic oil and how long is the replacement cycle? Today TD will briefly introduce how to choose hydraulic oil and the precautions for replacing hydraulic oil. Good use and maintenance can improve the stability and service life of the excavator. Users must not use inferior hydraulic oil to reduce costs to avoid irreversible damage to the excavator.

1. Hydraulic oil replacement cycle

The replacement cycle of hydraulic oil varies depending on the frequency of use of the excavator, the working environment and the quality of the hydraulic oil. In general, follow these recommendations for replacement:

1. New excavator or new hydraulic oil: In the early stage of use, it is recommended to replace the hydraulic oil every 50-100 hours to remove impurities produced during the running-in period.

2. Excavators in normal use: It is recommended to replace the hydraulic oil every 500-1000 hours, depending on the frequency of use of the excavator and the working environment.

3. Excavators under high load or harsh environment: The replacement cycle should be shortened and replaced every 300-500 hours.

2. Matters needing attention when replacing hydraulic oil

1. Select the appropriate hydraulic oil: Select the appropriate hydraulic oil viscosity grade and brand based on the excavator’s working environment, temperature, pressure and other conditions.

2. Thoroughly clean the hydraulic system: Before replacing the hydraulic oil, the hydraulic system should be thoroughly cleaned to remove impurities and moisture in the old oil.

3. Regularly check the quality of the hydraulic oil: judge whether the hydraulic oil needs to be replaced by observing changes in the color, smell and viscosity of the hydraulic oil.

4. Pay attention to safe operations: When replacing hydraulic oil, safe operating procedures should be followed to avoid safety accidents such as burns and fires.

3. Types of hydraulic oil that should be used in different environments

1. Low temperature environment: In low temperature environment, hydraulic oil with lower viscosity and lower pour point should be selected to ensure the normal operation of the hydraulic system.

2. High temperature environment: In high temperature environment, hydraulic oil with higher viscosity and higher flash point should be selected to prevent the hydraulic oil from overheating and deterioration.

3. High-humidity environment: In high-humidity environments, hydraulic oil with better anti-emulsification performance should be selected to prevent the hydraulic oil from emulsifying and deteriorating.

4. Dusty environment: In dusty environments, hydraulic oil with better filtering performance should be selected to prevent impurities from entering the hydraulic system.

4. Recommend several well-known hydraulic oil brands

1. ExxonMobil: As the world's leading petroleum and petrochemical company, ExxonMobil provides a variety of high-quality hydraulic oils suitable for various working conditions and environments.

2. Shell: Shell is an internationally renowned oil company. Its hydraulic oil products enjoy a high reputation in the market and have excellent lubrication properties and thermal stability.

3. Total: Total is a French oil company. Its hydraulic oil products are widely used in engineering machinery, ships, industry and other fields. They are favored by users for their high cost performance and stable performance.

4. Kunlun Lubricants: As a wholly-owned subsidiary of Sinopec, Kunlun Lubricants provides a variety of hydraulic oil products that meet international standards and are suitable for various domestic and imported engineering machinery.

5. Caltex: Caltex is a petroleum company headquartered in the United States. Its hydraulic oil products have excellent antioxidant properties and clean and dispersible properties, which can effectively extend the service life of equipment.

6. Fuchs Lubricants: Fuchs Lubricants is a German company known for its high-quality hydraulic oils. Its products have excellent anti-wear properties and can ensure stable operation of equipment under high loads.

7. Danfoss: Danfoss is a Danish company focused on providing high-quality hydraulic oil and lubricant products. Its hydraulic oils have excellent oxidation and shear stability, providing excellent equipment protection under extreme operating conditions.

8. Eaton: Eaton is an American company. Its hydraulic oil products are specially designed for construction machinery. They have good wear resistance and anti-corrosion properties and can ensure the stable operation of equipment in various harsh environments.

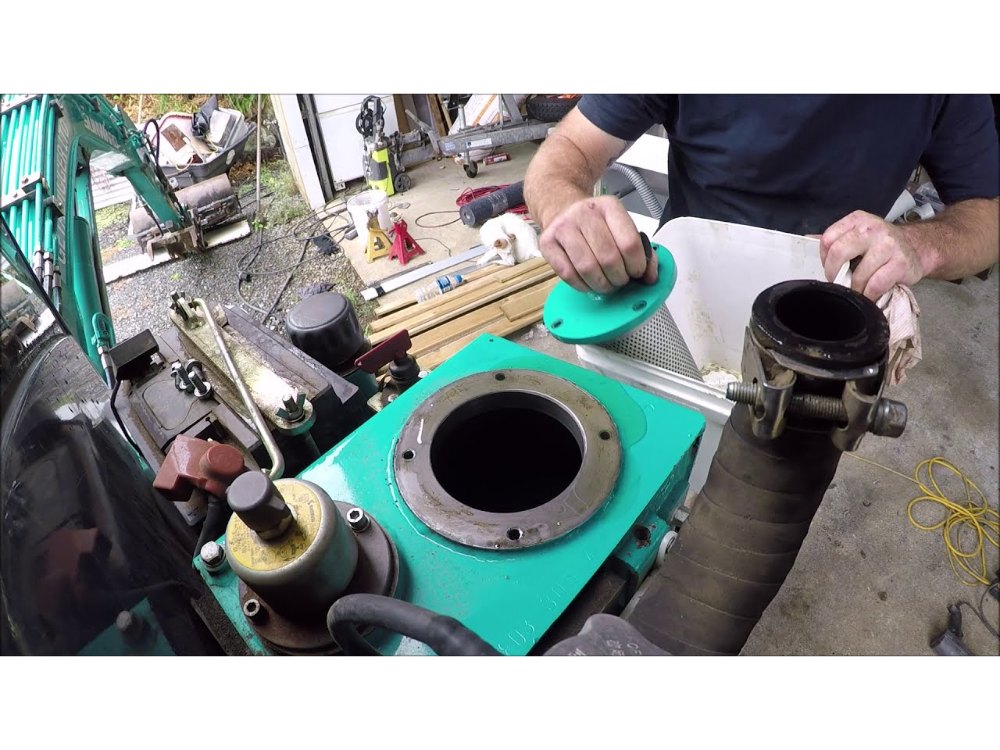

At present, the proportion of users who purchase used excavators is constantly increasing. Therefore, the hydraulic oil of used excavators needs to be fully maintained on the excavator in time, and the residual hydraulic oil needs to be cleaned and eliminated in time. Professionals or people who have the skills to replace it are needed. Or have experienced personnel perform the operation. When replacing the hydraulic oil, it needs to be completely eliminated, especially the preliminary preparations for replacement need to be done. The entire used excavator sold by TD has been fully maintained and maintained. However, the excavator needs to be drained of equipment oil when exported for foreign trade. The buyer needs to replenish and replace the equipment immediately to avoid losses.